General knowledge about compressor and refrigeration

Refrigeration technology has many applications, including air conditioning, refrigerator, water chiller, cold beverage machine, and industrial processes that require cooling. The specifics of the refrigeration system will depend on the specific application, but the basic principles of refrigeration remain the same.

- Compression: The refrigerant is compressed by the compressor, which raises its temperature and pressure.

- Condensation: The hot, high-pressure refrigerant flows into the condenser, where it releases heat to the surrounding air or water, causing it to condense into a liquid.

- Expansion: The liquid refrigerant passes through the expansion valve, which reduces its pressure and causes it to expand and vaporize.

- Evaporation: The low-pressure, cold refrigerant then enters the evaporator, where it absorbs heat from the surrounding environment, causing the refrigerant to evaporate and the environment to cool down. This is how the refrigeration system provides a cooling effect.

- Return to compression: The refrigerant then returns to the compressor to begin the cycle again.

Based on the working principle, it is easy to understand that the compressor is the heart of the cooling system, as the main refrigeration system component, then the refrigerant gas (Freon) is its blood. For many home-use refrigeration appliances, R134a or R600a are the 2 most commonly used refrigerants.

R600a VS R134a

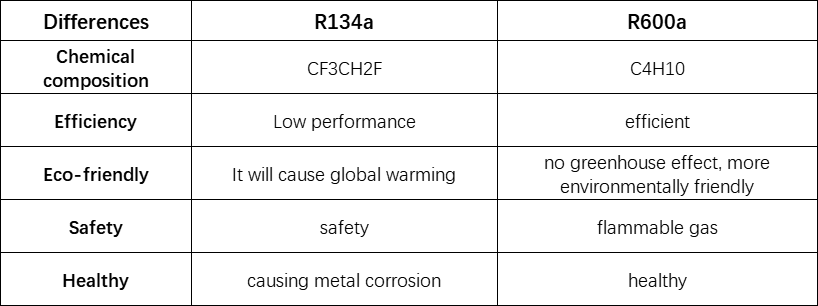

There are some key differences between the two.

- Chemical composition: R134a is a synthetic refrigerant that is made up of carbon, fluorine, and hydrogen atoms, the chemical formula is CF3CH2F. R600a, on the other hand, is a naturally occurring hydrocarbon that is made up of carbon and hydrogen atoms. the chemical formula is C4H10.

- Efficiency: R600a has a higher cooling performance and is more efficient than R134a. This means systems that use R600a require less energy to achieve the same level of cooling as systems that use R134a. We have to say that R600a has quite good refrigeration performance.

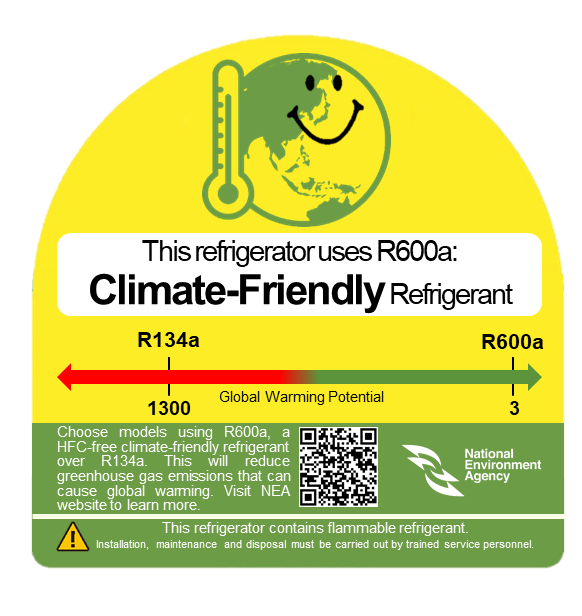

- Eco-friendly: R134a, also known as tetrafluoromethane, is a hydrofluorocarbon (HFC) refrigerant. It is a colorless gas that is used as a replacement for older refrigerants that have been found to have ozone-depleting properties. R134a has a relatively low global warming potential (GWP) of 1430. R600a is refrigerant-grade isobutane. It is a hydrocarbon refrigerant. It is a colorless gas that is used as a replacement for older refrigerants that have been found to have ozone-depleting properties, normally people talk about the ozone layer. R600a has a very low GWP of 3, which makes it an environmentally friendly option for refrigeration and air conditioning.R600a has no greenhouse effect. R600a’s evaporating pressure, condensing pressure, and exhaust temperature are lower than R-134a.

- Safety: R600a is a flammable gas, it can pose a safety risk if not handled properly. Additionally, some systems may need to be modified in order to use R600a, as it requires different operating conditions than R134a. And R134a is a very safe refrigerant.

- Healthy: R134A is soluble in water. If there is water present, it will produce acid, carbon monoxide, or carbon dioxide under the action of lubricating oil, causing metal corrosion. The refrigerant requires cleaning and drying of the system. R600A, on the other hand, is slightly soluble in water and is compatible with most metals, including aluminum, stainless steel, copper, and carbon steel.

In summary, we made the following form to have a general idea:

Conclusion

As we’ve compared, the R-600a is more efficient and has less environmental impact compared to the R-134a. However, the shortcoming of R600a is flammable. But most electric chilling appliances do not have enough gas to explode. Almost all countries have no restrictions on the initial installation of R600a refrigerant on new refrigeration equipment and its use in the after-sales maintenance process.

We recommend buying an R-600a water chiller for the long run.

Application of R600a and R134a for iWater under-sink water chillers

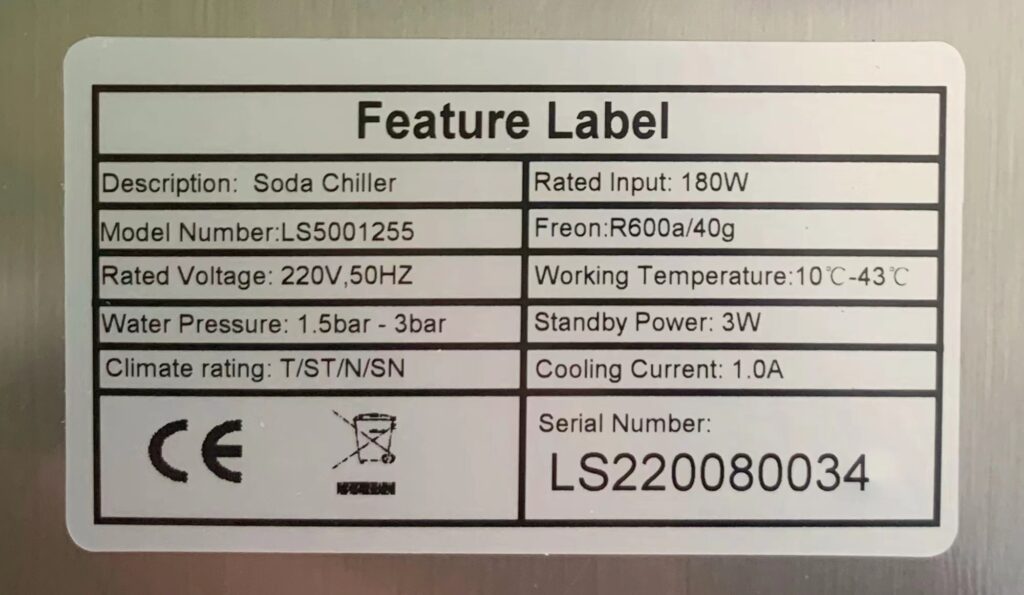

iWater has two refrigerant filling lines, one for R134a and one for R600a. As mentioned earlier, R600a is flammable, so the filling line has special requirements. The actual data below shows the difference in performance between R134a and R600a.

55 grams of R134a refrigerant filled and 40 grams of R600a refrigerant filled for the same cooling efficiency. Obviously, R600a has higher energy efficiency. R600a’s evaporating pressure, condensing pressure, and exhaust temperature are lower than R-134a. The lower liquid density of R600a refrigerant makes its charging capacity 45% of R-134a’s.

Meanwhile, as the compressor will work with exhaust temperature, the space under the kitchen is a relatively closed space, R600a exhausts less heat, and the working environment temperature of the chiller with R600a refrigerant is lower than the working temperature of the chiller with R134a refrigerant.

From global warming potential point of view, R600a has no impact on the greenhouse effect. R134 has a certain greenhouse effect. R600a has no greenhouse effect.

So more consumers consider choosing iWater under-kitchen water chiller with R600a refrigerant.

Application of R600A

As highlighted earlier, R600A has become the refrigerant of choice because of its eco-friendly properties. Let’s look at some of the applications of this refrigerant. The refrigerant used in geothermal power generation R600A is ideal for industrial refrigeration It’s applicable in beverage dispensers. And our refrigerator, and which one is better? Given its low Global Warming Potential, R600A has grown in favor throughout the years (GWP). As a result, it is now the ideal refrigerant for light commercial and home refrigeration devices such as freezers, freestanding display units, refrigerators, and beverage dispensers. The refrigerant is non-toxic, has no ODP, and performs exceptionally well in thermodynamics.

In commercial refrigeration, R290 is also a commonly used refrigerant, with R290 having a slightly higher cooling capacity than R600a. However, their specific application needs to be selected according to the requirements and performance of the specific commercial beverage machine.